Innovation and Lightness: Advanced Aluminium Engineering

In the field of industrial casting, Mazzucconi stands out for its innovative approach to aluminium engineering, enhancing its unique combination of lightness and strength.

The use of aluminium not only enables a significant reduction in component weight, but also leads to overall improvements in product performance — a key advantage in the automotive sector, where weight reduction is essential for energy efficiency and vehicle dynamics.

With more than a century of experience, Mazzucconi has reached the highest standards of casting expertise, shaping aluminium into complex geometries while maintaining structural integrity and minimizing imperfections.

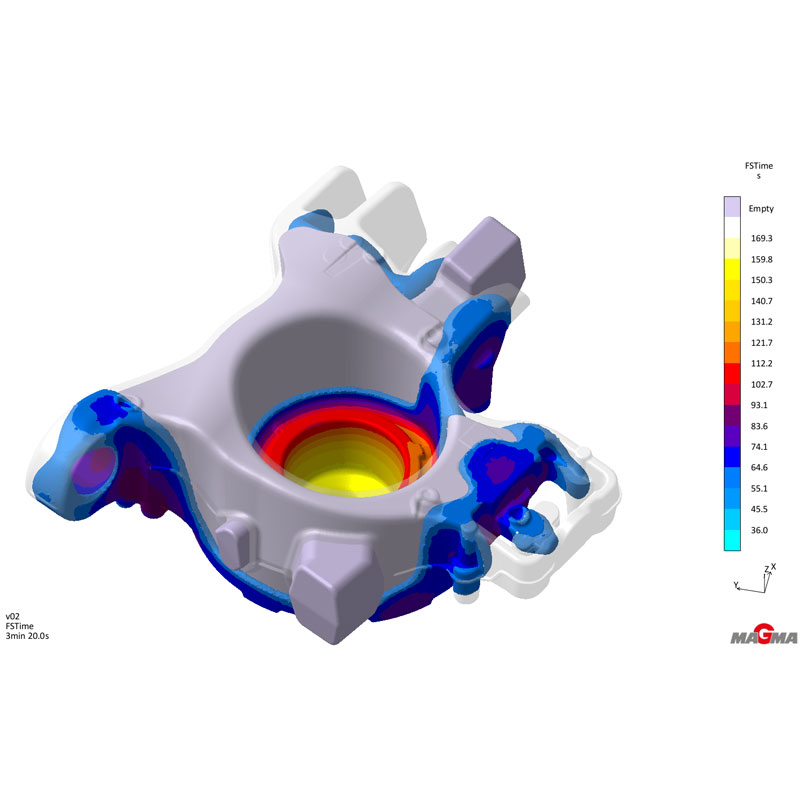

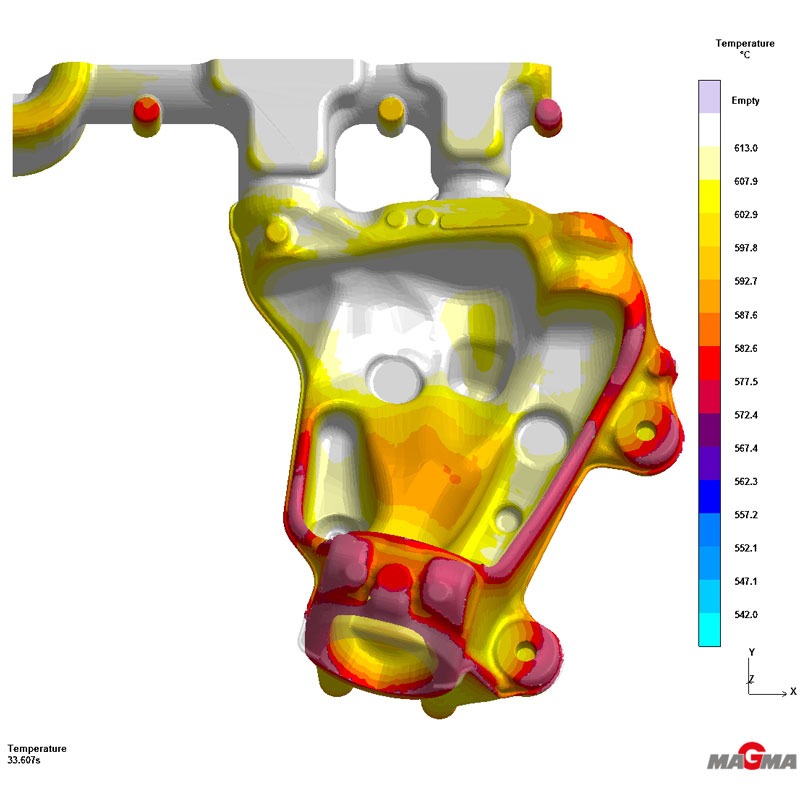

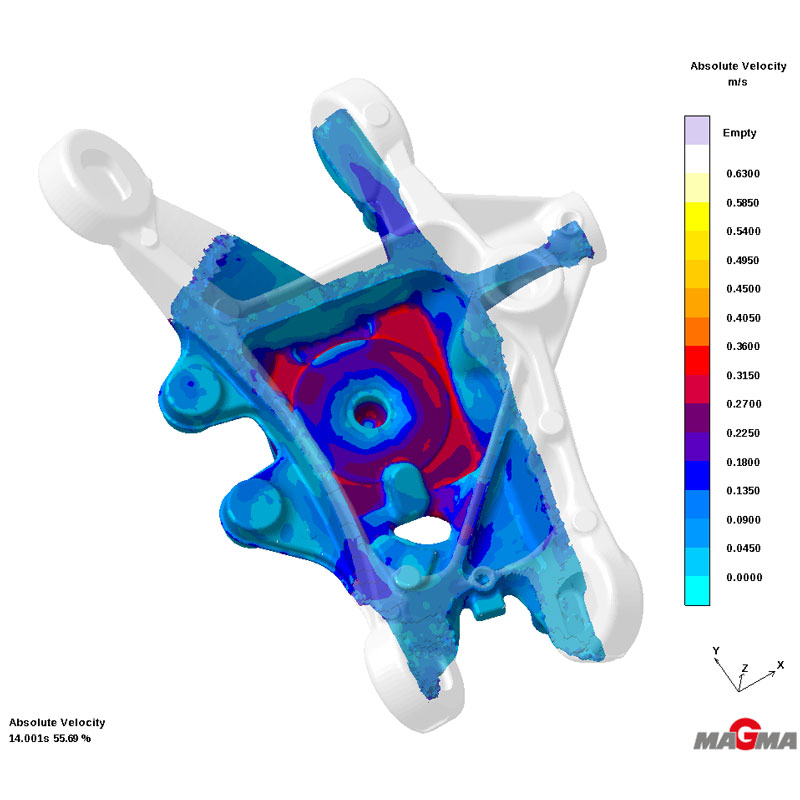

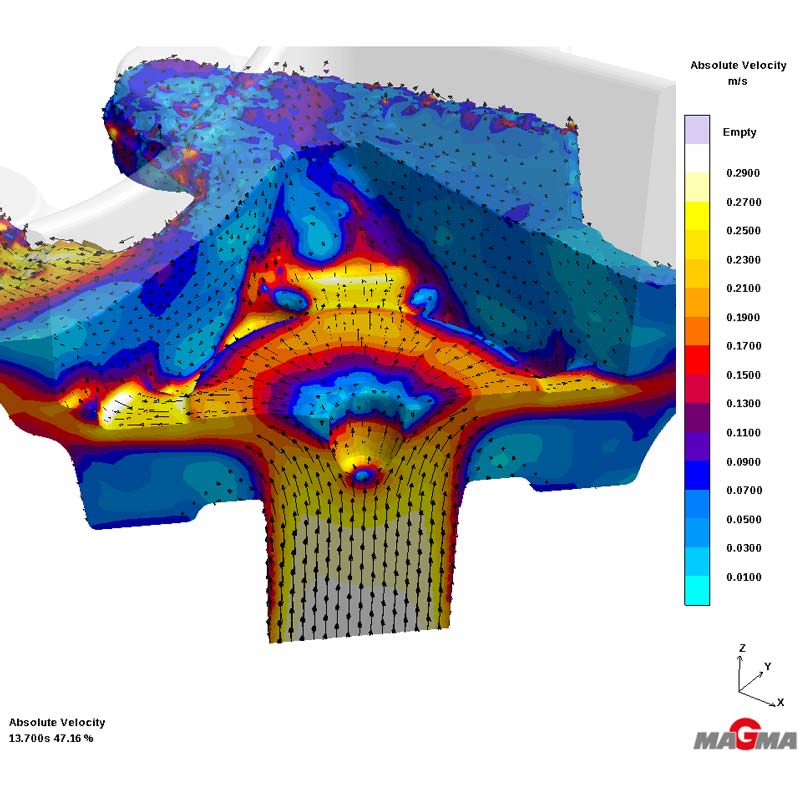

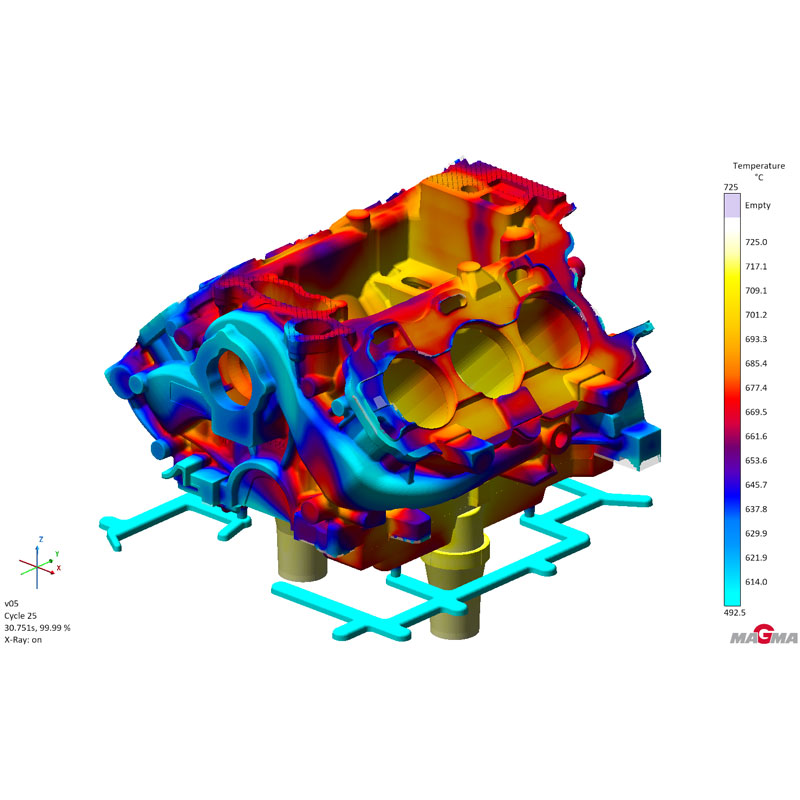

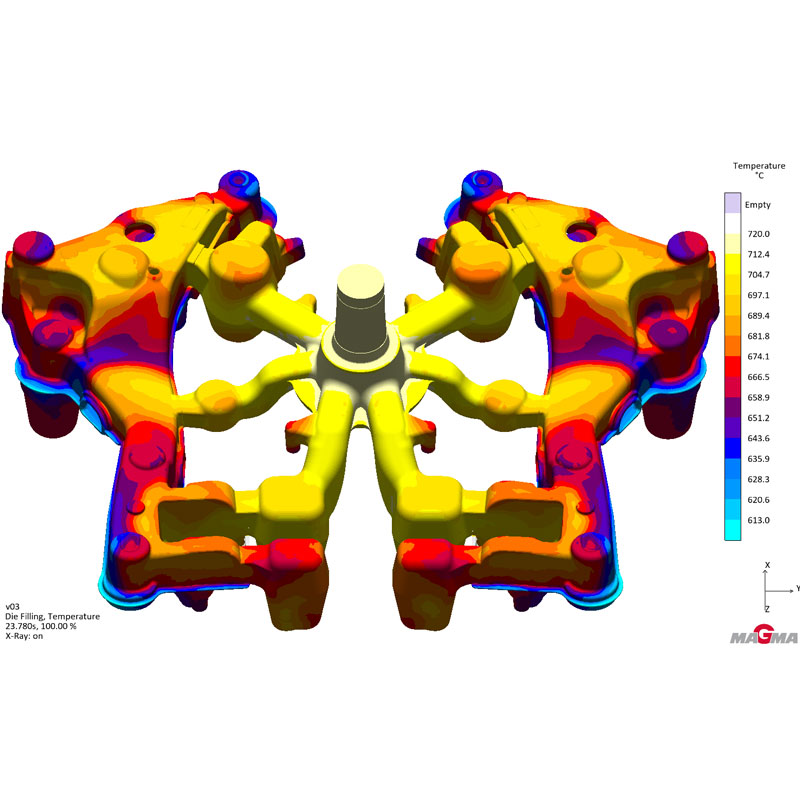

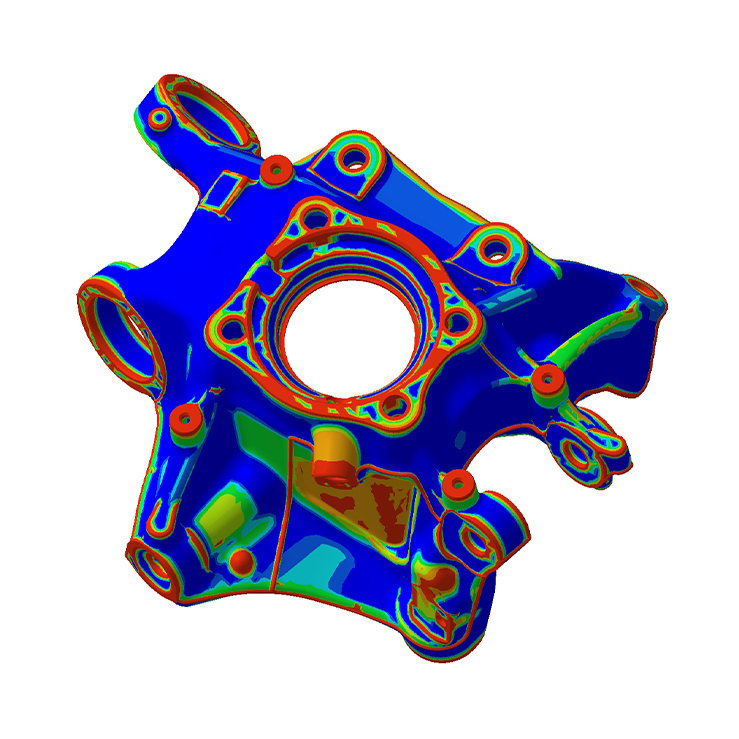

We combine this know-how with state-of-the-art simulation technologies that accurately predict material behaviour under stress, optimize design for load distribution, and identify potential weak points — ensuring precision and reliability from concept to production.

Innovation and Lightness: Advanced Aluminium Engineering

In the field of industrial casting, Mazzucconi stands out for its innovative approach to aluminium engineering, enhancing its unique combination of lightness and strength.

The use of aluminium not only enables a significant reduction in component weight, but also leads to overall improvements in product performance — a key advantage in the automotive sector, where weight reduction is essential for energy efficiency and vehicle dynamics.

With more than a century of experience, Mazzucconi has reached the highest standards of casting expertise, shaping aluminium into complex geometries while maintaining structural integrity and minimizing imperfections.

We combine this know-how with state-of-the-art simulation technologies that accurately predict material behaviour under stress, optimize design for load distribution, and identify potential weak points — ensuring precision and reliability from concept to production.

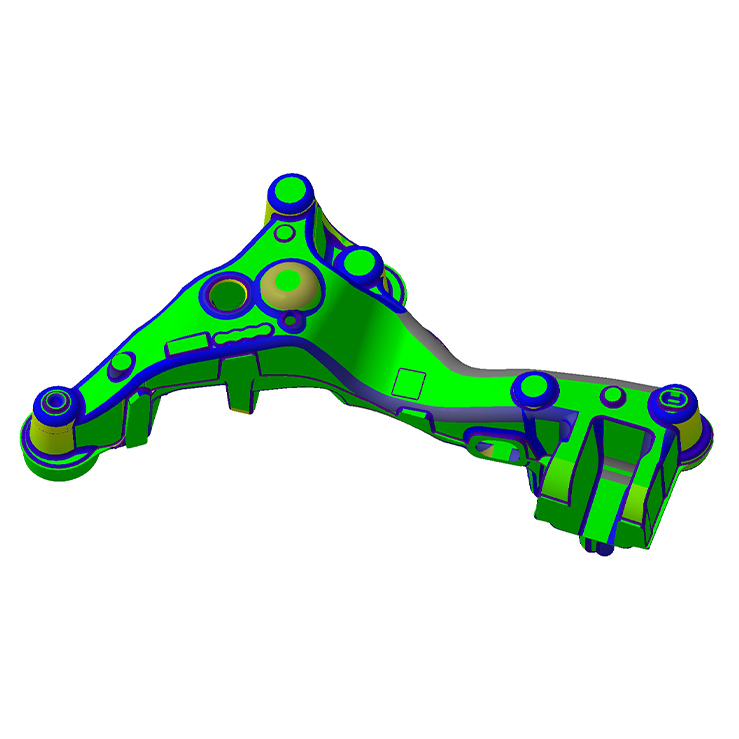

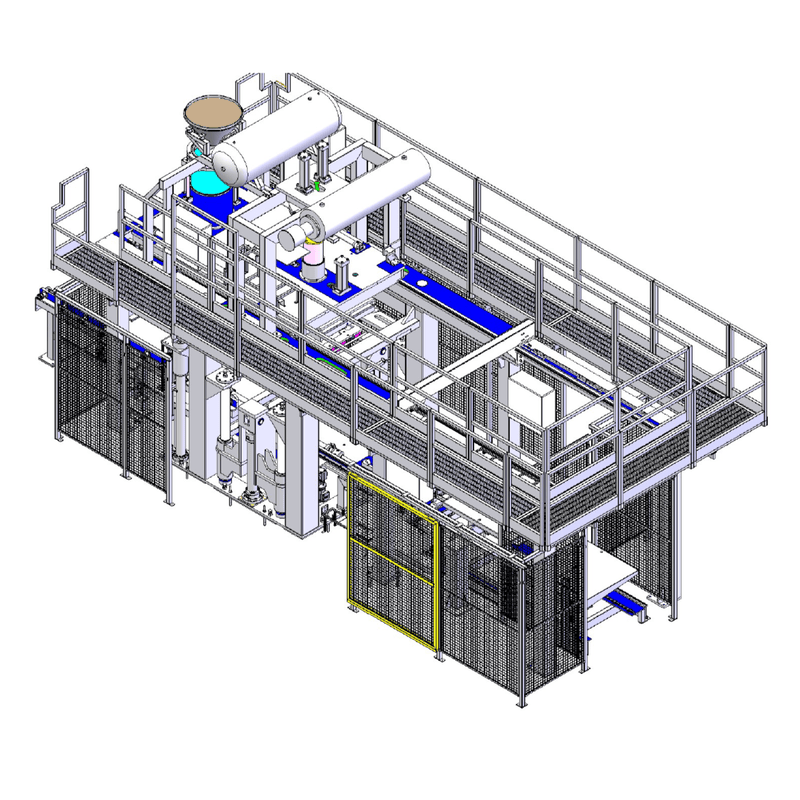

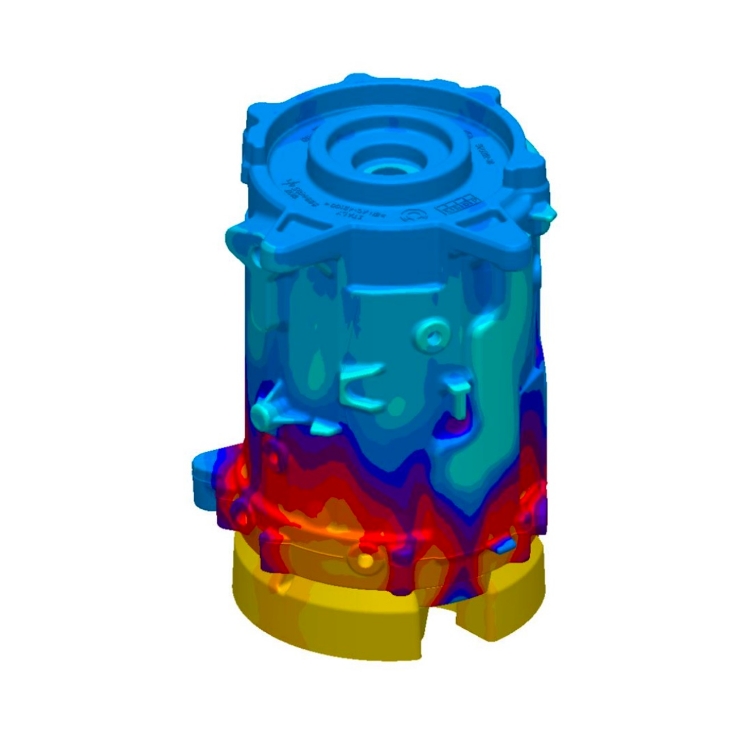

Casting Process

Selecting the right casting process is crucial for manufacturing high-performance, safety-critical components.

Our advanced casting methods guarantee parts with tight tolerances and optimal material properties.

Through low-pressure and gravity casting technologies, we meet the most demanding technical and lightweight requirements of our clients.

Mazzucconi’s engineering competence in foundry processes translates directly into finished components that combine mechanical strength with weight reduction, ensuring maximum efficiency and durability.

- Low-pressure die casting

- Gravity die casting

- High-pressure die casting

Filling, solidification, cooling, stress and deformation analysis, porosity evaluation.

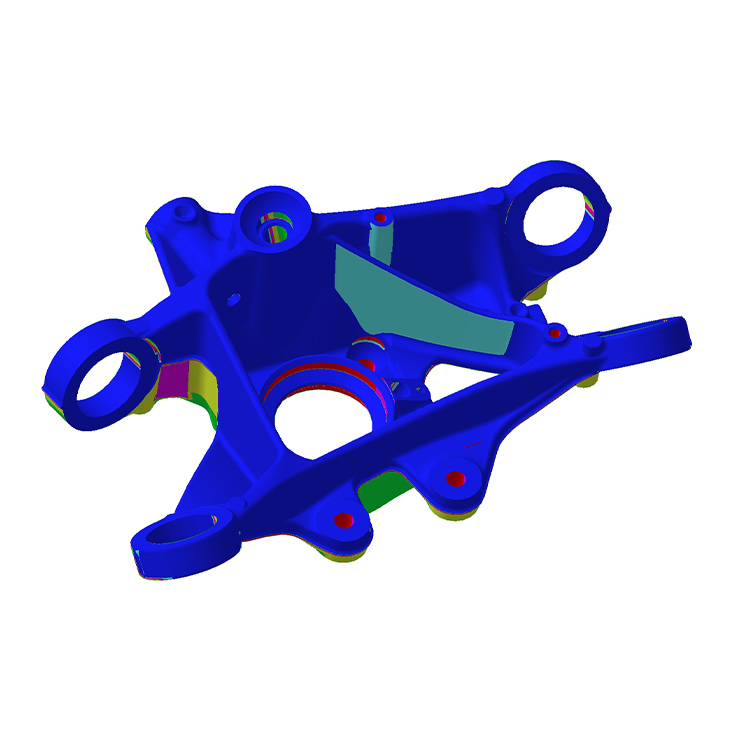

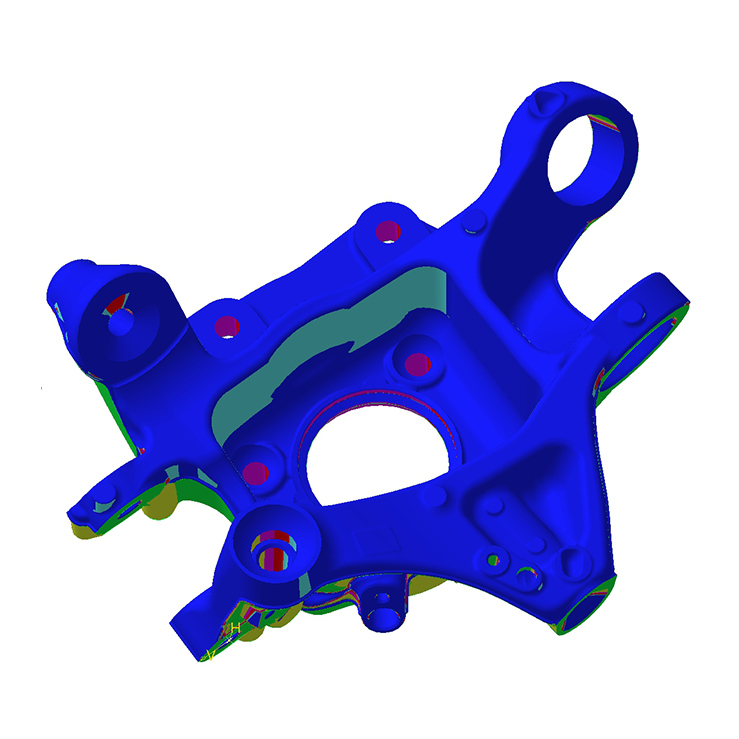

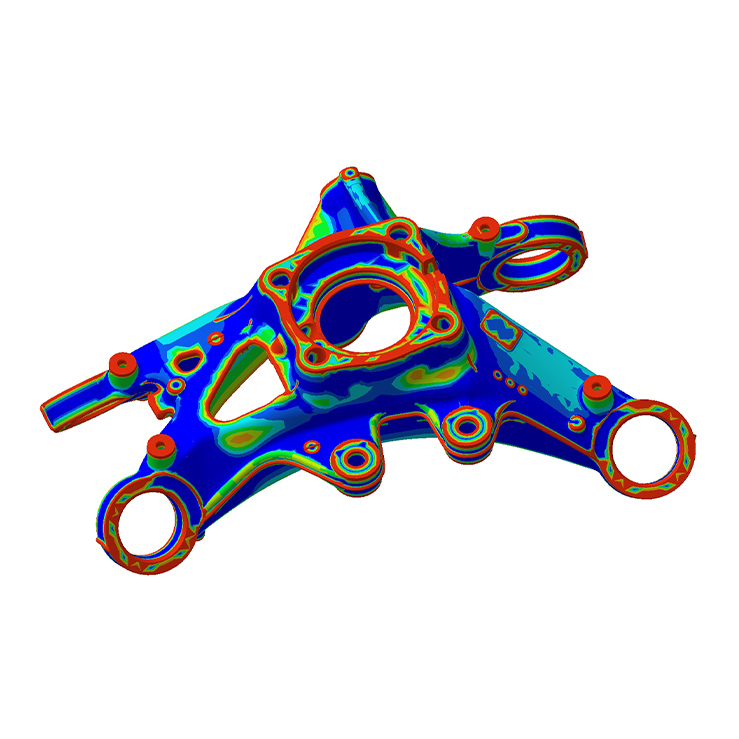

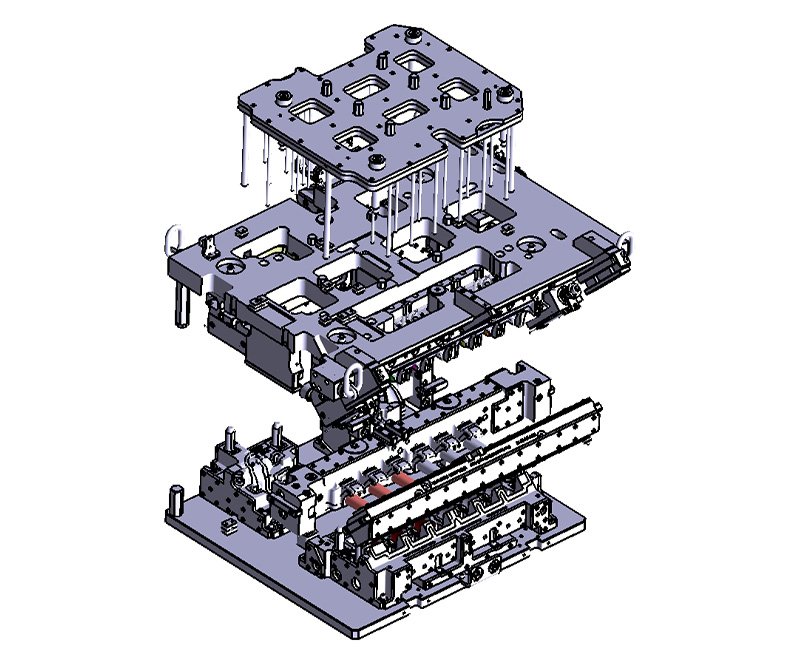

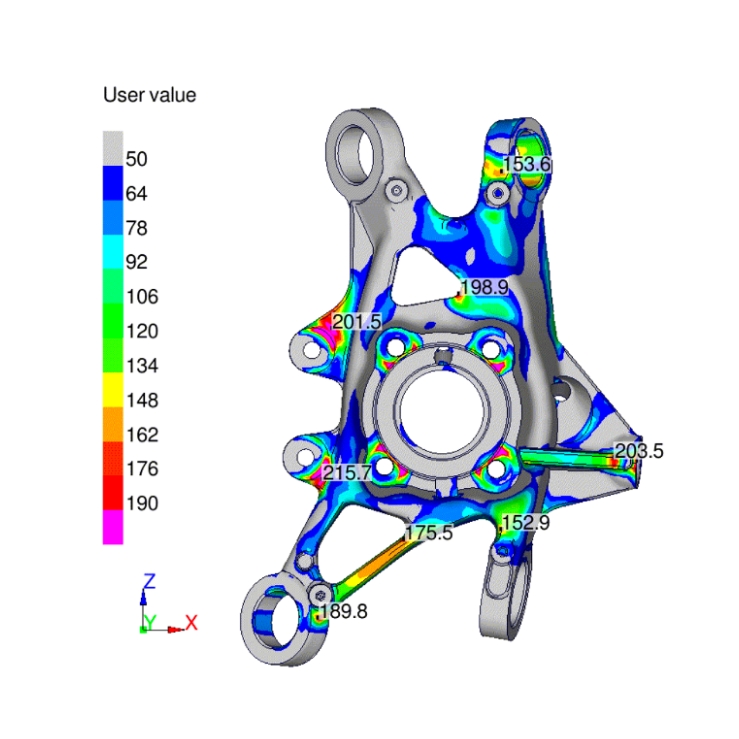

Technical-Executive Definition

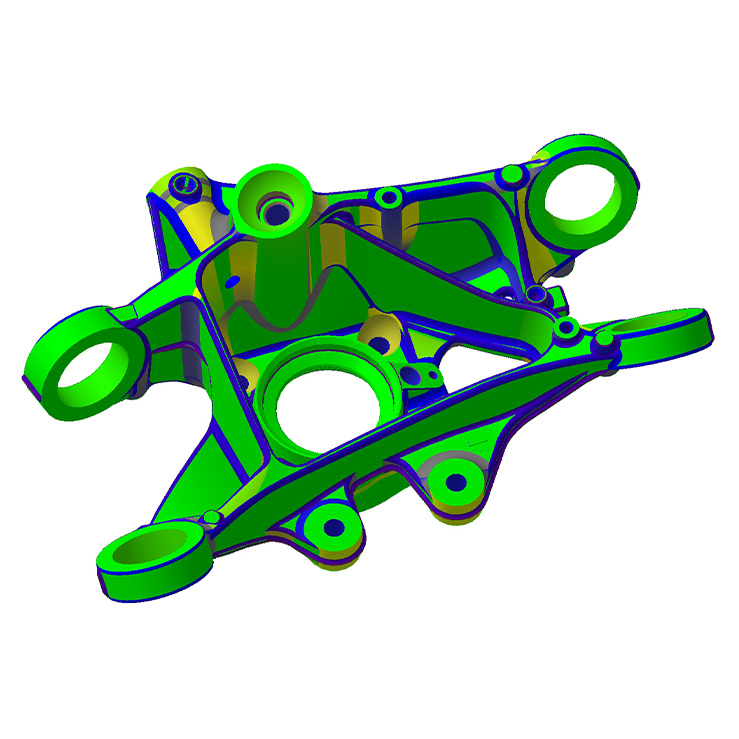

The executive phase integrates precision technical design with advanced product simulations.

This combined approach ensures that every component is optimized for performance and durability before entering production.

Using sophisticated Finite Element Method (FEM) simulations, we predict and solve potential structural issues early in the process, ensuring that the final design meets all technical specifications.

This method allows for accurate validation and higher production efficiency, achieving minimal scrap and consistent quality.

Technical design and engineering of product geometry.

- Stress analysis simulation

- Physical mechanical resistance testing

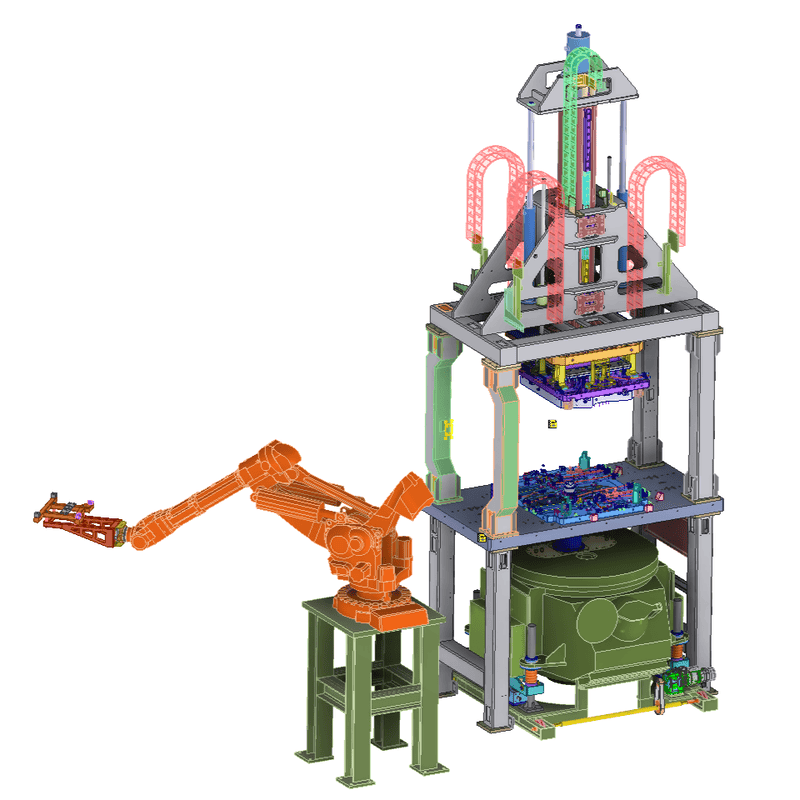

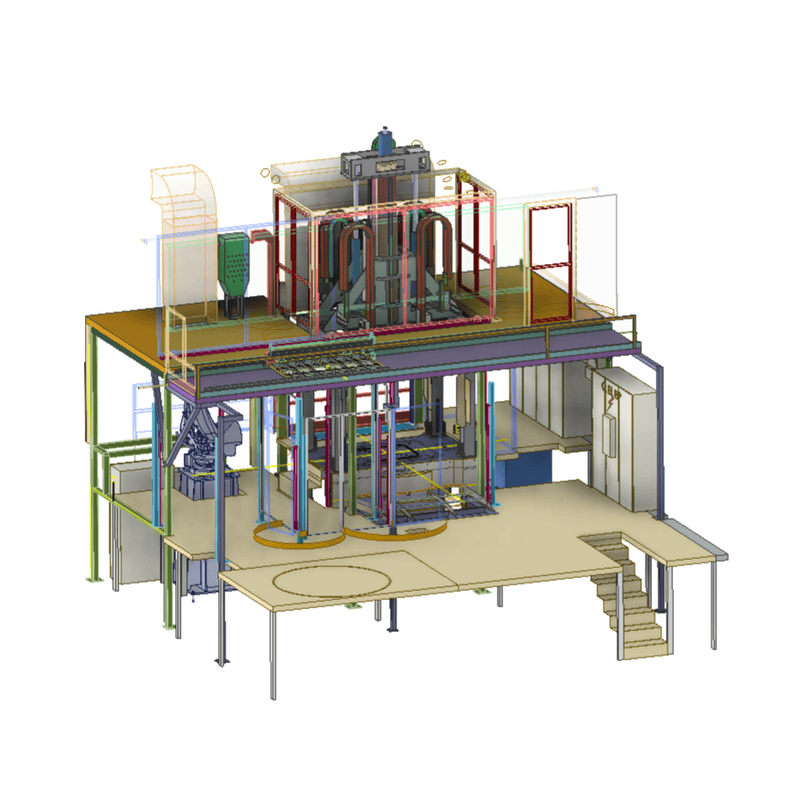

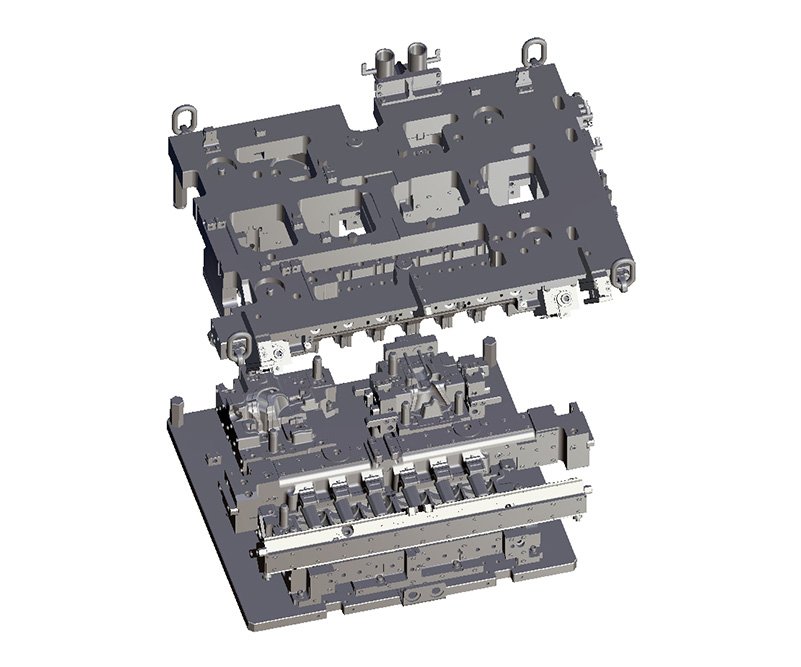

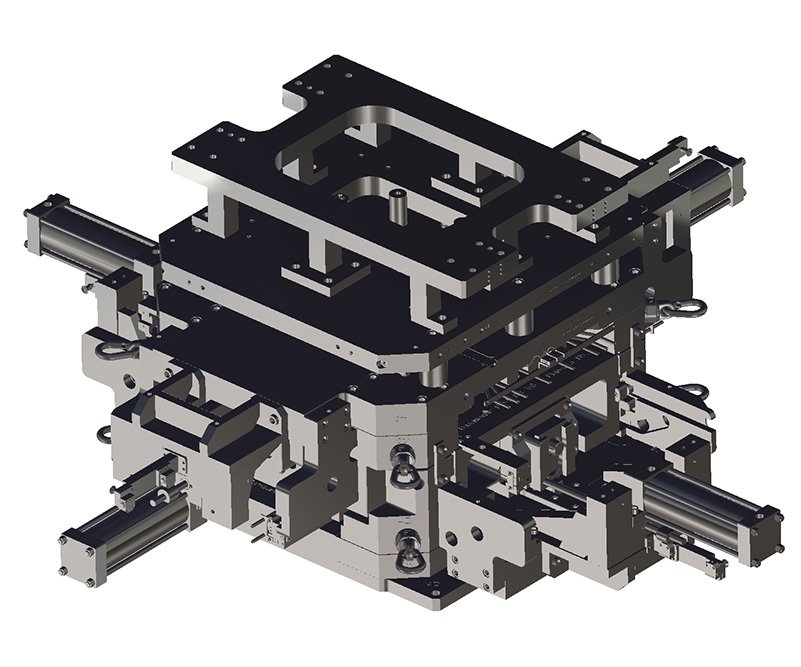

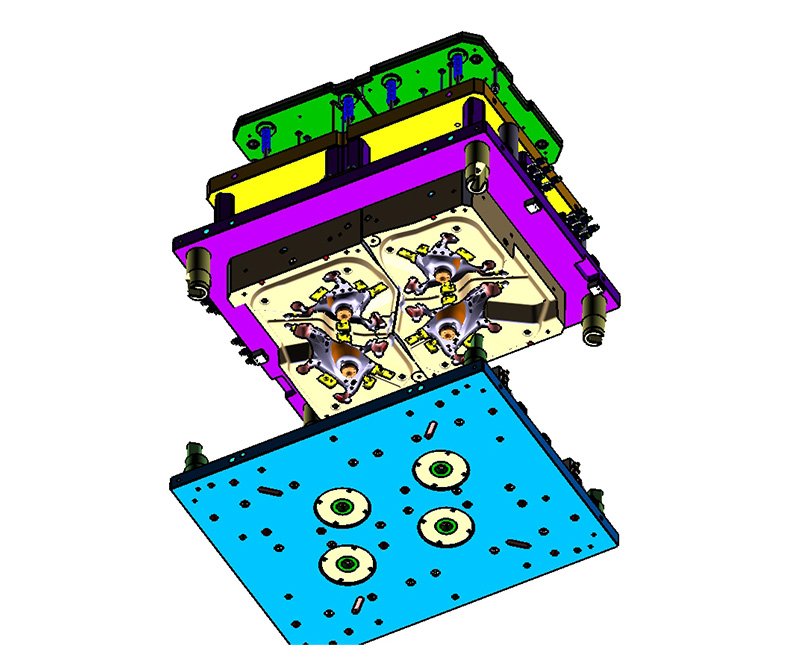

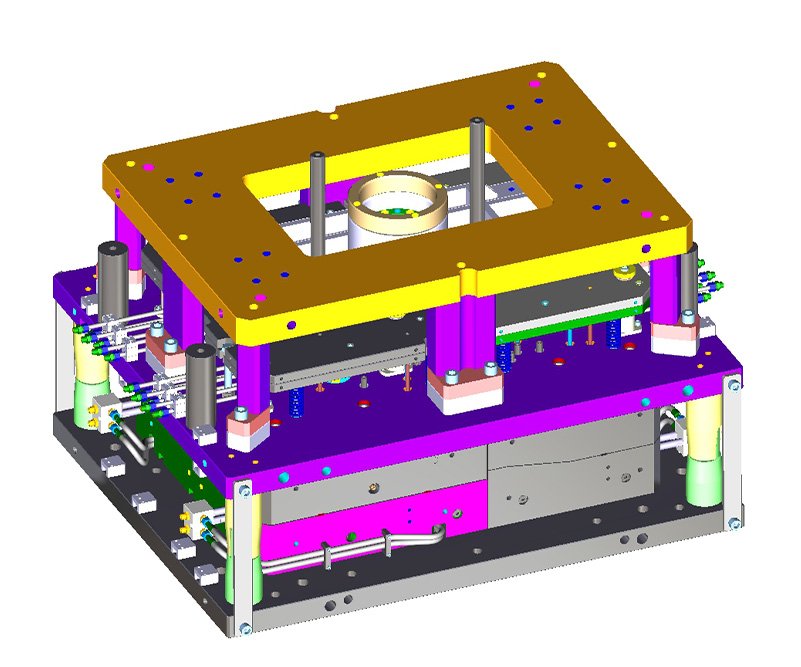

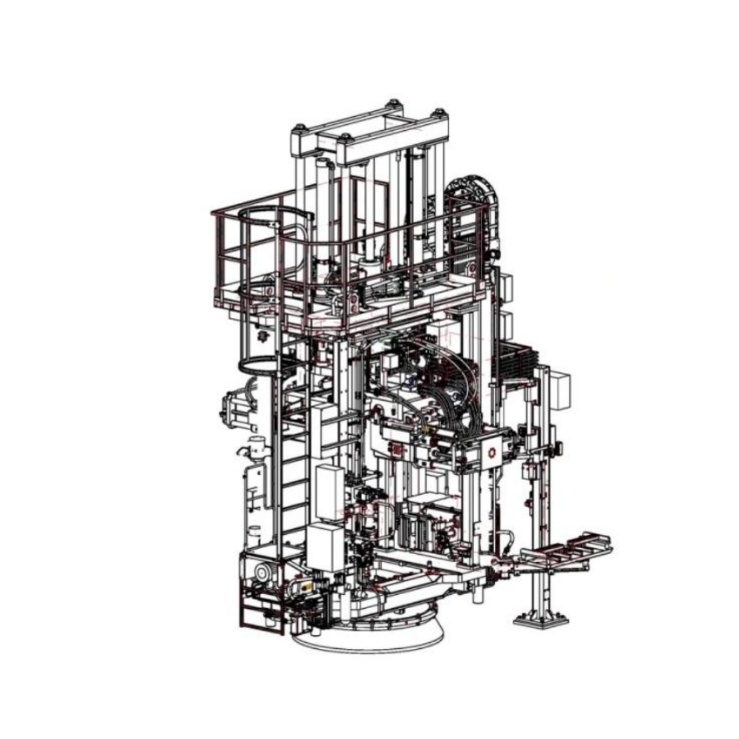

Efficient Machinery Construction

We customize every aspect of the production process.

The machinery developed in-house is designed to perfectly meet the specific requirements of our production systems, integrating the latest technological innovations.

This approach ensures that each machine not only meets production demands optimally but also contributes to greater efficiency, precision, and final product quality.

- Low-pressure casting machines

- Tilt gravity casting machines

- Sand core production systems

– Foundry installation and commissioning

– Development of tooling and integrated production process

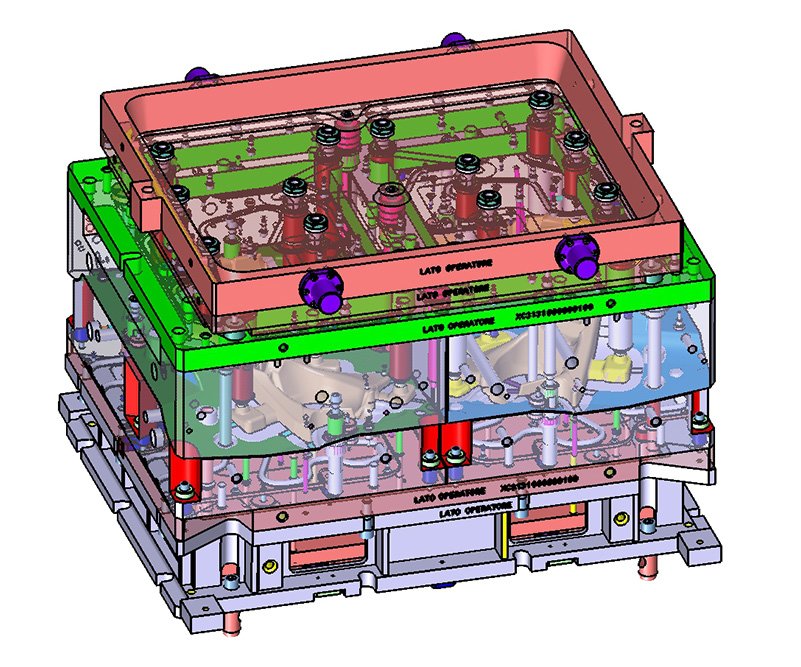

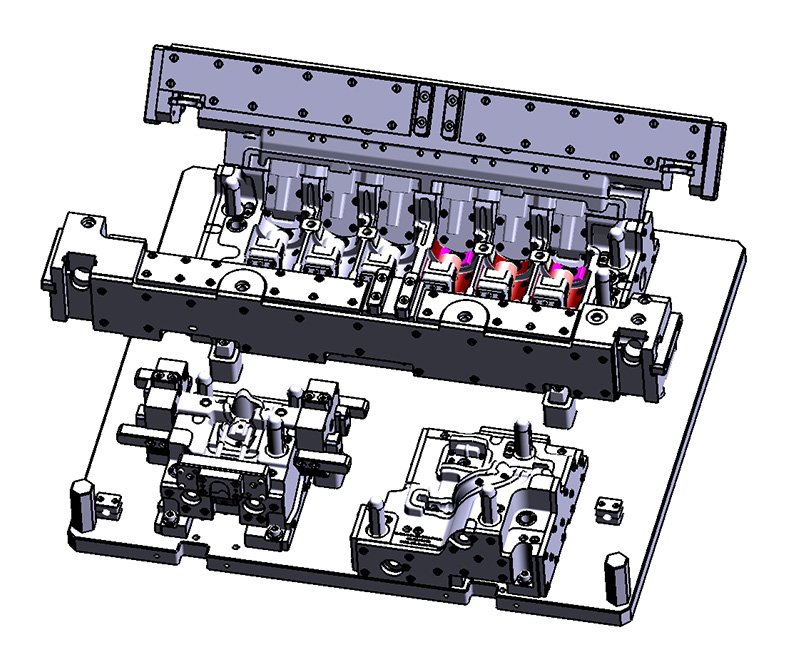

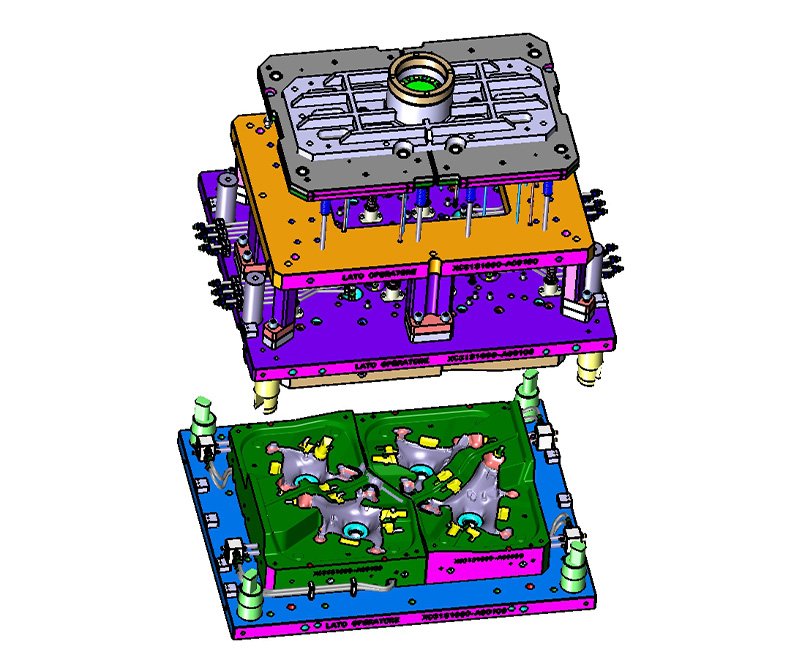

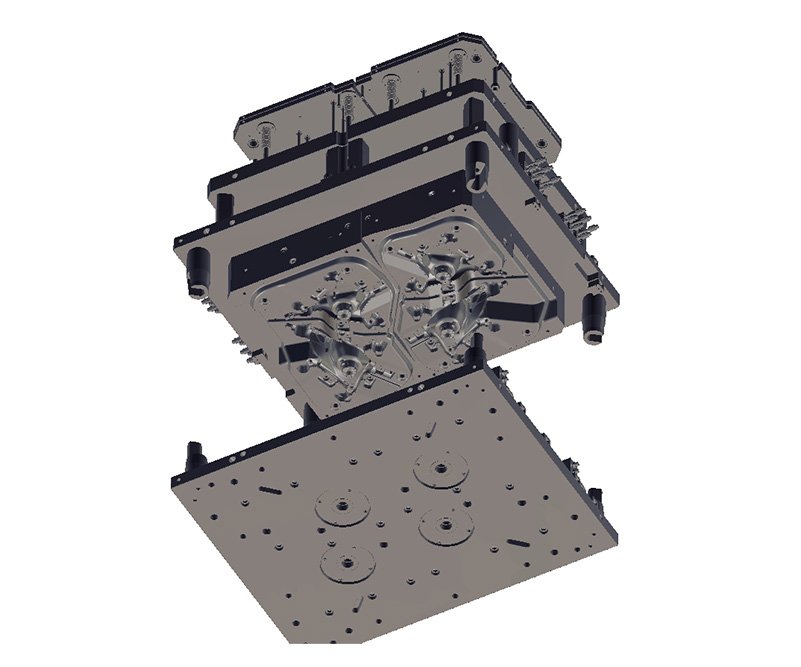

High-Performance Equipment

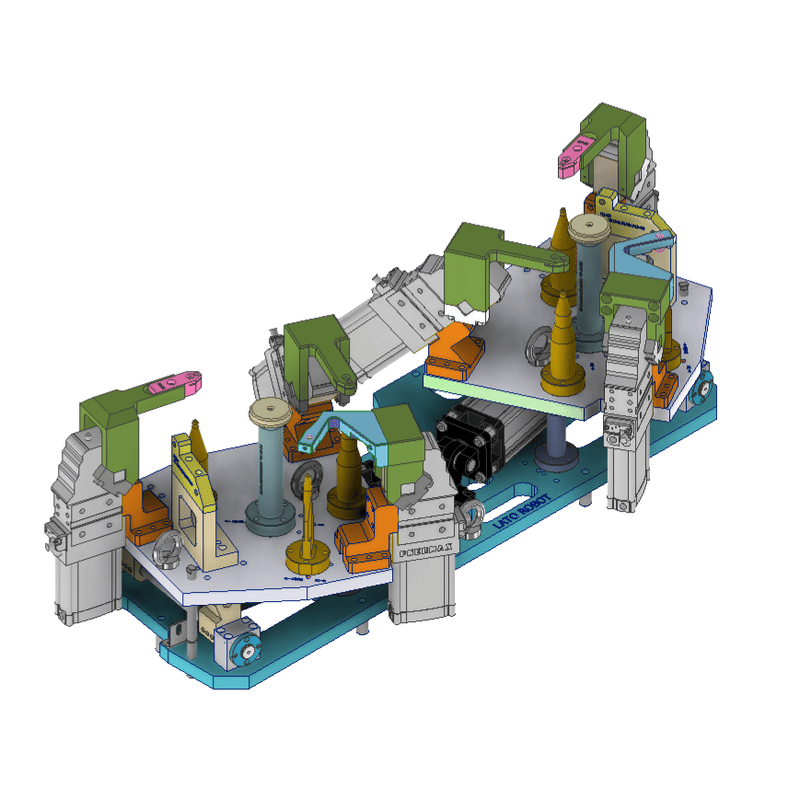

The design of production tooling is a cornerstone of our strategy to ensure operational excellence and product quality.

This process involves developing tailor-made equipment precisely aligned with the client’s technical specifications and production requirements.

These custom solutions optimize manufacturing, maximize efficiency, and reduce cycle times.

Thanks to our in-house engineering expertise, we design and build all tools internally, maintaining strict control over quality and process precision, a key factor behind Mazzucconi’s reputation for reliability and performance.

- Geometry and material analysis

- Evaluation of the production cycle and required volumes

- Definition of mechanical, structural, and functional requirements of the tooling

- Molds and dies

- Core boxes

- Clamping and handling fixtures

Talk to us. Let yourself be guided into the future of technology.

Contact us to start a collaboration focused on high-value technological solutions — our team is ready to help you shape your next industrial achievement.